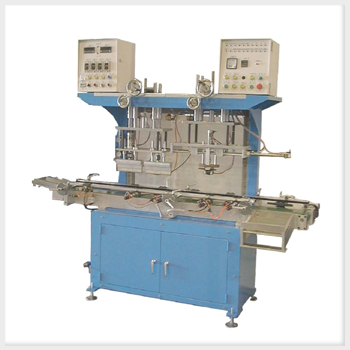

KAC-20M(2R)

Air Leak Testing & Coding Machine For Motorcycle Battery

This Air Leak Testing & Coding Machine provides to leak testing and code the manufacturing date or number for motorcycle battery to check condition of heat-sealing between the container and cover of battery automatically.

Sequence of Operation

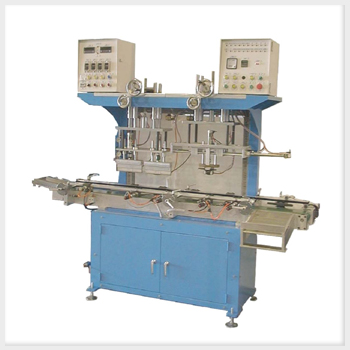

After the battery is completed the process of heat-sealing, this battery is delivered to this leak testing machine by conveyor. When a battery enters the testing area automatically located and stopped in the situation. Then the sucking tool will automatically go down to press the vent holes of battery and start sucking. The leak testing cycle is completely automatic under user's setting. If the battery is detected leaked, the air pressure was lost (may read the figure from meter) and the alarm sound, then the machine rejects the battery automatically. Upon completion of the leak test, then the good battery will be conveyed to the next coding area automatically and the coding head goes down to proceed cycle work, and then the coded battery is passed to output for next process.

Feature

- It is equipped with PLC computer controlling system.

- It is easy to set the testing term and can get the high rate of accuracy

- It is easy to adjust the up-down moving distance of testing tool and change the testing tool efficiently.

- Its pressure system equipped with a safety system. If the pressure is not enough, this Air Leak Testing & Coding Machine will be stopped and alarmed automatically to avoid the defect testing.

- Cycle duration approx. 280~360 pcs/hr. (20-25 sec./cycle) (2 batteries)

Utilities Requirement

- Electricity: 3 phase, voltage and frequency to suit customer's specifications.

- Compressed air consumption: 45nl/min. at 6 kg/cm²

Dimension and Weight

- Approx. 2350(L) x 1060(W) x 1920(H) mm

- Approx. 600 kgs

Other

Assembly Line For Automotive Battery, Semi-Automatic Assembly Line For Motorcycle Battery, BatteryMachinery.